The chiller removes heat from a load and transfers it to the environment using a refrigeration system. This heat transfer device is the preferable cooling machine in power plants and other large-scale facilities. It is simply a system consisting of ethylene water or water reservoir and circulation components. The cooling fluid is circulated from the reservoir to the equipment under cooling. There are also air-cooled chillers, which disperse heat-using fans.

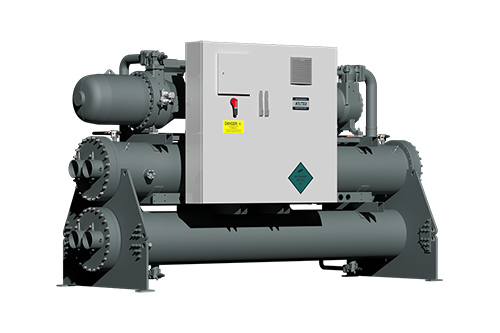

Water Cooled Chiller

Water-cooled chiller systems have a cooling tower, thus they feature higher efficiency than air-cooled chillers. Water-cooled chillers are more efficient because they condense depending on the ambient temperature bulb temperature, which is lower than the ambient dry bulb temperature. The lower a chiller condenses, the more efficient it is.

What are the benefits of a water-cooled chiller? Water chillers because of the smaller size they occupy as compared to air-cooled chillers. These chillers also feature higher efficiency and last longer than the mentioned alternative.

In The Evaporator

The role of the evaporator is to produce chilled water. The device releases the water at about 6 °C (42.8°F) and pushes it throughout the facility with the help of a pump. We need to know how to pipe water chiller, a network of pipes passes the chilled water through every necessary section of the building. After exchanging coldness with room air, which blows across the Air Handling Units (AHU’s) and fan coil units (FCU’s), the water is now warmer at about 12 °C (53.6°F). It returns to the evaporator where the refrigerant absorbs the unwanted heat and directs it to the condenser. The chilled water is cool once again and it can now continue to cool the facility.

In The Condenser

A refrigerant brings unwanted heat from the evaporator and passes through the condenser. There is another loop connected to the condenser the condenser water loop, which is between the cooling tower and the condenser. After entering the condenser at about 27 °C (80.6°F), the water leaves at 32 °C (89.6°F) and heads to the cooling tower.

In The Cooling Towers

This is where the unwanted heat in a facility ends up. A large fan feeds the unit with air. The air meets with the oncoming condenser water. From the direct contact, the condenser water loses heat to the air. The condenser water goes back to the condenser the cycle continues.

Air Cooled Chiller

Where aesthetics and environmental conditions or water access restrictions exist, the air-cooled chiller may be applied. Both air-cooled and water-cooled chillers depend on an air stream as a means of heat transfer. The difference is that the water-cooled chillers or rather the cooling towers use a humid air stream (ambient air stream + water spray) while the air-cooled chillers use a current of ambient air. Normally water-cooled chillers are cheaper and more efficient, with the disadvantage of high water consumption. When used in part-load applications, these chillers are very reliable.

In summary, here are the benefits of using air-cooled chillers:

- No cooling towers.

- Better environmental stability-no water wastage.

- Low maintenance costs.

- Easier to operate and control-tower freezing and tower bypass absent.

- Chemical costs avoided.

- Water costs avoided, especially in cities.

- No water problems to deal with in case of disaster.