Chiller systems are essential for temperature control and cooling in several industries. Choosing the right kind of industrial chiller for process and space cooling can lower cooling costs, minimize downtime, and improve operational efficiency.

This article will cover the different types of chillers for commercial and industrial applications, as well as the pros and cons of each. The aim is to help you make an informed buying decision.

Types of Industrial Chillers (Based on Condenser Type)

The three major types of industrial chillers in use today are air-cooled chillers, water-cooled chillers, and evaporative condensed chillers. Let’s take a closer look at all three:

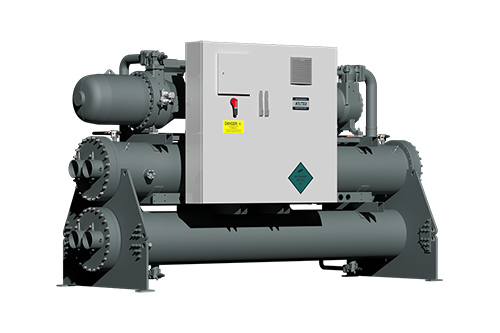

Water-Cooled Chillers

The most common types of water chillers use water from an external tower to cool the gaseous refrigerant in the condenser. After expelling its heat, the refrigerant undergoes a phase change into a liquid and is recirculated into the system.

The Pros

1. Water-cooled chillers are generally more efficient than air-cooled chillers.They have a quieter operation than air-cooled systems.

2. They are suitable for both small-scale and commercial-scale cooling.

3. Portable water chiller troubleshoots are available for facilities with space constraints.

The Cons

1. Water-cooled chillers can be costly to install and maintain due to the additional cooling water tower, tanks, and water pump.

2. Since they require a constant supply of water for cooling, they might not be suitable for locations with water shortages or restrictions.

3. Water-cooled systems require periodic condenser water treatment to prevent the formation of mineral deposits in the system.

Air-Cooled Chillers

Air-cooled chillers use ambient air to reject heat from the refrigerant in the condenser before condensation and recirculation. Additionally, air fans attached to the unit help speed up the cooling process.

The Pros

1. Portable solutions are available for facilities with space constraints.

2. Air-cooled chillers are available for small-scale and commercial-scale cooling depending on sizing and chiller capacity.

3. They are cheaper to install and maintain than water-cooled systems.

4. The heat ejected from the chiller can be used to warm the facility during cold periods, providing additional cost and power savings.

The Cons

1. Air-cooled chillers use cooling fans which produce some level of noise from water chiller.

2. The life expectancy of an air-cooled chiller can be less than that of a water-cooled chiller.

Comparison Between Air-cooled and Water-cooled Chillers

While the components of both air-cooled and water-cooled chillers are mostly the same (condenser, expansion valve, evaporator, and compressor), the main difference is in how the refrigerant is cooled. In an air-cooled chiller, hot refrigerant entering the condenser is exposed to atmospheric air which rejects the heat before it condenses back to its liquid state. On the other hand, in a water-cooled chiller, hot refrigerant gas is sent to a water-cooled heat exchanger or condenser, and the refrigerant is cooled using water from a cooling tower. For a better understanding, learn how cooling towers and chillers work together.