ATO air cool water chiller applicable for cooling molds to reduce products molding cycle, also they are available in the cooling of equipments in order to maintain a normal temperature. Besides, they are suitable for other industries with the need of cooling.

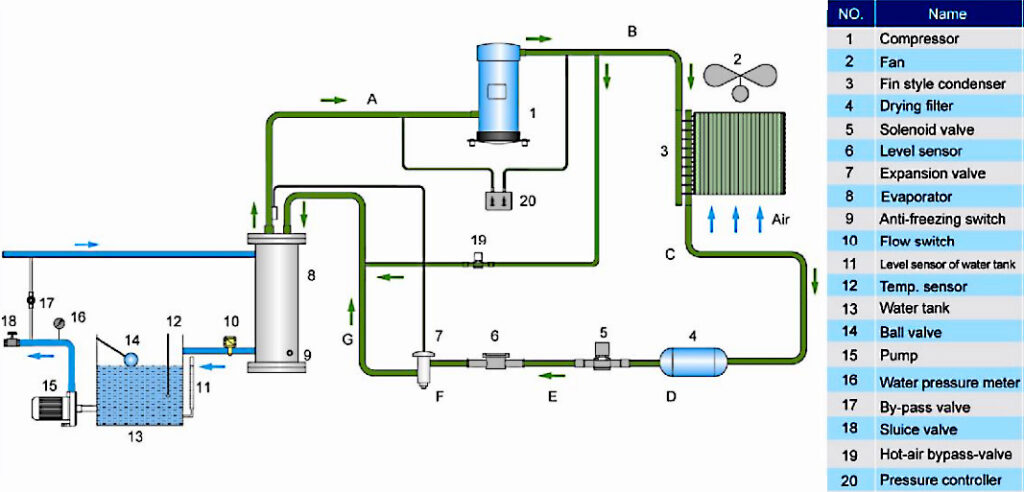

When the ATO air cooled water chiller starting up, compressor starts working. Refrigerant is compressed into high temperature high pressure gas in the process from B to C, and then be cooled when passing through the condenser and changed into liquid. Heat is taken away by the cooling air. In the process from C to D to E and F, the liquid refrigerant is dried and filtered by the dry filter.

After that, it passes through the solenoid valve, level sensor and then reaches the expansion valve. In the process from F to G, the high pressure liquid refrigerant is throttled and depressurized by the heat expansion valve and the temperature goes down. In the process of G to A, chilled water absorbs the heat of process water in the evaporator and returns back to the compressor. This heat exchange process repeats until process water is cooled down to required temperature.

Hot-air bypass function: the compressor continues working when the working process of water chiller is cooled down to the required temperature, then the hot-air bypass valve opens as the temperature drops to its set value. A part of the refrigerant from the compressor passes through the bypass valve and then reach the evaporator, balancing out part of the machine refrigerating capacity and then goes back to the compressor without passing through the condenser. With the help of hot-air bypass valve, the system can stay in an balanced condition and meanwhile can keep the control accuracy at ±1 ℃.